Technology

Early Technology Adoption: The Key To Helm’s Reputation for Accuracy and Excellence

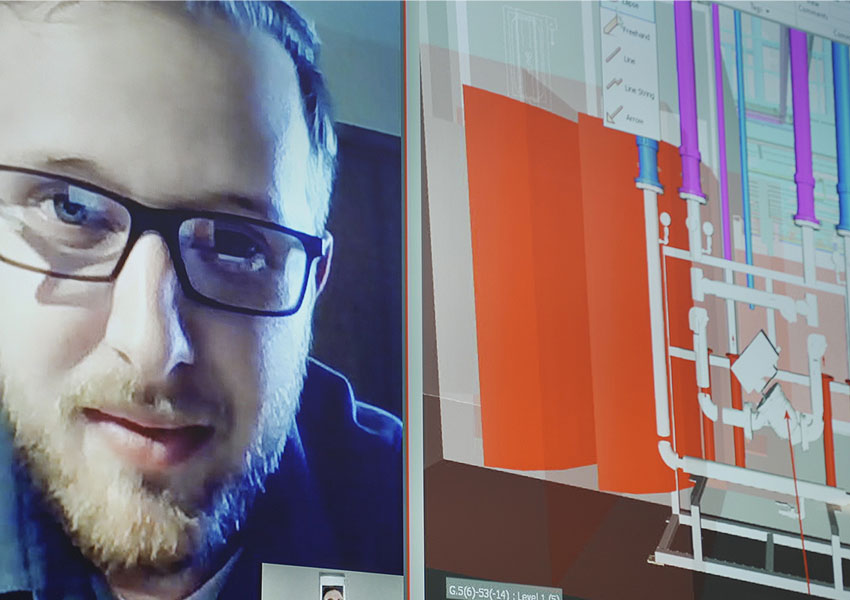

Helm’s early technology adoption has always been focused on productivity improvements. We find that when we are able to give the field the same real-time information that our project management staff have access to, we improve not only the efficiency on a project, but the quality and safety as well. Much of our productivity enhancement using technology comes from having easy access to the building model. In addition, our paper-less system and digitization of all project information allow us to always work off of the latest information and speed the flow of data between members of the project team. Our ERP system can easily be accessed by the field, our RFIs and submittals are all in electronic form and easily accessed from a tablet, and our building model is not only available to view, but also mark up and change right at the fabrication shop or project site. When our systems are digitized, productivity tracking and improvement become easier and a standard operating procedure.

We like to say that we are not only leading edge with our technology, but also bleeding edge. We are regularly asked to be a beta tester of a new technology offering and were early collaborators on some of the most industry-changing technology that is not commonplace today. We believe in early involvement of emerging technology because it gives us a jump start on industry adoption, but it is also a great tool in recruiting new talent into the company. Recent high school grads, college grads, and trade apprentices work here because we aren’t afraid to experiment. When we see the impact that a recent high school grad has made in programing a new product for us, we realize we have something special and different. For more on our career opportunities, click here.

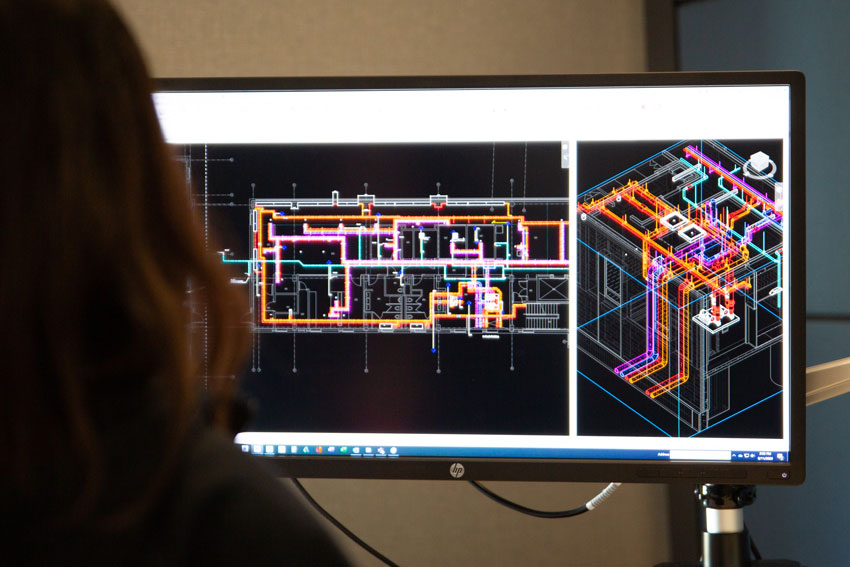

Building Information Modeling (BIM) is the core element of Helm’s renowned Project Management System. It drives nearly all construction preplanning and execution activities. BIM actively engages our entire corporate team. As early adopters and drivers of BIM, our familiarity with and commitment to our custom-developed planning process is a primary reason why Helm can be counted on to deliver accuracy and excellence time and again.

At Helm, we have been using parametric 3D modeling technology to detail our projects since 1999 and we have developed unmatched expertise in the discipline. Currently, with more than 30 in-house BIM/VDC Technicians, we employ a carefully selected combination of best-in-class software technologies to maximize workflow efficiency, accountability and to help us meet both specific and general project goals.

The primary goal of the BIM approach at Helm is to jointly develop a fully-coordinated, fully constructible integrated virtual model of the project long before construction begins. In creating the model, we focus on the most efficient layout of equipment, component routing, component supports, sleeves and penetrations. We thereby avoid potentially costly cross-trade interferences in the field.

We also look for opportunities to share resources with other contractors for mutual benefit. Through the use of pre-fabricated hangers, Trimble Laser Guided Total Station Units and pre- fabricated piping and duct spools and module assemblies, the BIM process allows us to unload our trucks directly into the installed hangers at predetermined installation locations. This advanced practice maximizes efficiencies and minimizes material handling, packaging and overage waste. It reduces on-site labor and maximizes productivity and safety.

In other recent developments, Helm has begun exploring how Augmented Reality (AR) can enhance operations and processes in the construction industry with an eye toward bringing even more advances in efficiency to our clients’ critical projects. By employing Hololens, we anticipate AR being used in at least 3 distinct applications: project visualization, imaging and Visualization during construction and also by enhancing service and maintenance post-construction.

You can rest assured that at Helm our quest for increasing accuracy and efficiency through technology will never end. To begin a conversation about how we employ technology to benefit our clients’ projects, please send us an email. We’ll get right back to you. Tell us a little about your needs. We will respond promptly.

Current Software & Applications:

- Full Autodesk AEC Suite

- Autodesk Construction Cloud (BIM 360)

- Trimble Robotic Total Stations

- Faro Focus S70 Laser Scanner

- Bluebeam Revu and Studio Sessions

- Industry standard file sharing

- Microsoft Office 365

- All industry standard remote conference options

- Hololens 1 and 2 with HoloLive 3D

- Visual Live for iPad

- StructionSite photo documentation

- DADO Intelligent File Search

- GTP Stratus, eVolveMEP, and VicTools for BIM to Fabrication