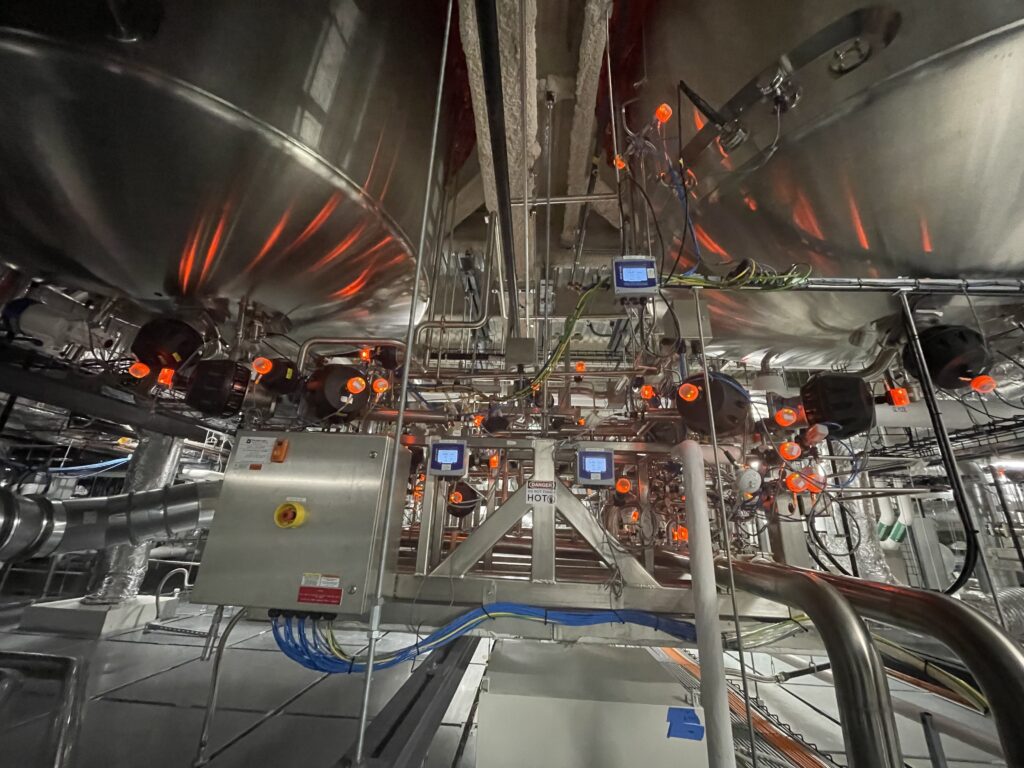

Industrial Process Piping

Unparalleled Expertise for Every Industrial Need

At Helm, we’re not just in the business of providing solutions, we’re in the business of powering progress. With a steadfast commitment to excellence and proven track record of success, we stand as your trusted partner in optimizing your industrial operations.

An Engineering News Record-recognized leading specialty contractor in the Midwest, we’ve provided some of the most technically challenged advanced building process systems in the industrial market segment. Our turnkey solutions are customized for complex projects for the chemical, industrial manufacturing, renewable energy, automotive/EV, refining/petrochemical, biotech, pharmaceutical, environmental, industrial glasses, and food and beverage industries.

With decades of experience under our belt, Helm brings unparalleled expertise to every project, combining technical prowess with innovative thinking to deliver solutions. We’re proud to be one of the largest employers of skilled and qualified tradespeople in the industrial industry.

Since 1946, Helm’s three, state-of-the-art fabrication facilities – which includes 8,000 square feet of clean room space for hygienic fabrication – and multiple offices throughout the Midwest positions us well to respond to even the most complex projects. Our documented best-in-class safety record, schedule performance, and technical compliance complements our industrial areas of expertise below.

Let Helm bring the power of our industrial capabilities to your next project. Send us an email to start a conversation today. We will respond promptly.

Helm’s Industrial Process Piping Areas of Expertise

- Preconstruction

- Design, engineering, and construction

- Virtual Design and Construction (VDC) and Building Information Modeling (BIM)

- 3D scanning

- Process and high purity piping prefabrication and field installation

- Skid fabrication and modulization

- ASME pressure vessel repair and fabrication

- Project quality management

- Equipment settling

- Service, maintenance, and commissioning

- Regulatory compliance

Welding Certifications and Processes

Certifications of Authorizations

- ASME “PP”

- ASME “U”

- NBIC “R”

Welding Codes

- ASME Section IX

- API-582 Supplemental Requirements

- Client Specific Requirements

Codes of Construction

- ASME B31.1

- ASME B31.3

- ASME B31.5

- ASME B31.9

- ASME BPE

Our Defining Centers of Excellence

- Innovation & early adoption of the finest technology

- Highest quality standards for quality craftsmanship

- Enduring commitment to building information modeling

- Decades of multi-industry experience

- Long-tenured, highly talented management team

- 24/7 service